Guidance on the Use of the Lifting Fatigue Failure Tool (LiFFT)

Version 1.4.1 - Last updated 08/26/2019

| Using LiFFT | | | Mono-Task | | | Multiple Tasks | | | Highly Variable Tasks |

The LiFFT risk assessment tool is an easy to use method of evaluating the risk associated with manual lifting tasks. It is based on fatigue failure theory, which is the theory that assesses the cumulative damage of materials subjected to repeated stress. There is substantial evidence that low back pain (and other musculoskeletal disorders) are the result of an accumulation of damage in musculoskeletal tissues due to repetitive stress (Gallagher and Schall, Jr., 2017). The LiFFT tool has been validated against two epidemiological databases in which the LiFFT cumulative damage measure showed strong associations with low back disorders and back pain (Gallagher et al., 2017).

Using LiFFT

The purpose of the LiFFT tool is to determine the cumulative low back load experienced during a workday. Based on LiFFT’s cumulative damage measure, a probability that the job is high risk is calculated. A high-risk job is defined as a job having 12+ injuries per 200,000 hours worked (Marras et al., 1993).

All that is needed to use the LiFFT tool are three pieces of information on each lifting task: 1) the weight of the load; 2) a measurement of the greatest horizontal distance from the hip joint to the center of the load during the lift (using a measuring tape); and 3) the number of repetitions of this task during the workday. Figure 1 below demonstrates how the maximum distance from the hip joint to the load should be measured.

Assessing Mono-Task Jobs

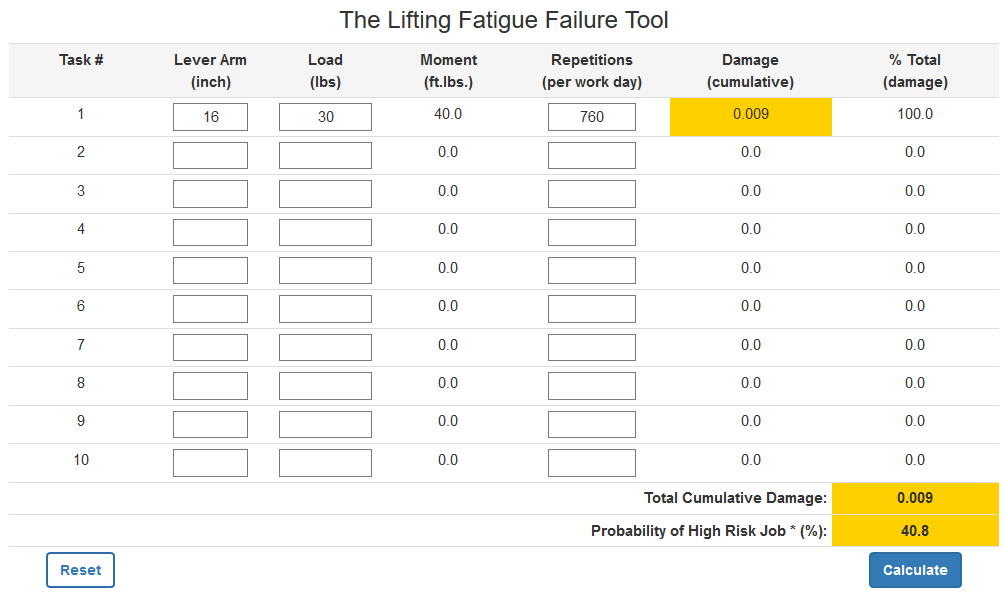

The simplest example of applying LiFFT to analyze lifting demands is that of a mono-task job (i.e., a job involving the same lifting task all-day long). In this example, the job involves a lift of a 30-pound load that is performed 760 times during the workday, involving a maximal horizontal distance of 16 inches. Figure 2 below shows a screenshot of the LiFFT tool for this mono-task job, which demonstrates this job has a 40% probability of being a high-risk job.

Assessing Jobs with Multiple Lifting Tasks

For jobs involving multiple lifting tasks during the workday, each individual lifting task should be analyzed using the method above. The cumulative damage associated with each lift will be summed by the LiFFT tool to determine the daily dose of cumulative spine loading. An example is provided in Figure 3 below.

The example above shows that the combination of these three tasks leads to a combined probability of 51% that this would be a high-risk job. Further, note that task #3 accounts for about 81% of the total damage for the workday. This task would be a prime candidate for redesign. For example, if the lever arm for task #3 were reduced to 15 inches, the probability that the overall job is high risk would be reduced to 38%.

Assessing Highly Variable Lifting Jobs

If a large number of highly variable lifting tasks is performed (for example, warehouse picking), a “binning” procedure can be used. In this procedure, lifts within the same range of peak moments are summed together and the cumulative damage score is developed using the number of lifts within each “bin”. For example, one might have 130 lifts between 0-10 ft.-lbs., 75 lifts between 11-20 ft.-lbs., and so forth. These can then be entered into the tool using the top load moment of the range (10 ft.-lbs., 20 ft.-lbs., etc.), and the cumulative damage for the workday can be determined. An example is shown in Figure 4 below.

While all of the “bins” individually result in low to moderate risk, the overall probability that these tasks represent a high-risk job is moderately high at 48%.

References

Gallagher, S., Schall Jr., M.C. (2017) Musculoskeletal disorders as a fatigue failure process: evidence, implications and research needs, Ergonomics, 60: 255-269.

Gallagher, S., Sesek, R. F., Schall, M. C., & Huangfu, R. (2017). Development and validation of an easy-to-use risk assessment tool for cumulative low back loading: The Lifting Fatigue Failure Tool (LiFFT). Applied Ergonomics, 63, 142-150.

Marras, W.S., Lavender, S.A., Leurgans, S.E., Rajulu, S.L., Allread, W.G., Fathallah, F.A., Ferguson, S.A. (1993). The role of dynamic three-dimensional trunk motion in occupationally-related low back disorders: The effects of workplace factors, trunk position, and trunk motion characteristics on risk of injury. Spine 18(5): 617-628.

Marras W.S., Allread W.G. and Ried R.G. (1999). Occupational low back disorder risk assessment using the lumbar motion monitor, Chapter In: Karwowski W. and Marras W.S., (Eds.), The Occupational Ergonomics Handbook (Boca Raton: CRC Press), pp. 1075–1097.

Version history

V1.4.1 - 08/26/2019: added function for metric input; added link to DUET;

V1.4.0 - 06/05/2018: updated damage - risk relationship;

V1.3.0 - 11/06/2017: updated damage - risk relationship and color coding calculation;

V1.2.0 - 03/26/2017: initial release.